219

3826

Perpetual Research

Showing a computer rendering of the watch to the world is one thing; developing and producing working watches for the end collector is another. Add to the mix that you have included semi-precious gem stones as integral parts of the cog wheels in the drive train, and that there is no known way of doing this yet, and someone, somewhere along the way will have to come up with some very smart and original ideas. This is not just Richard’s triumph, but all the watchmakers and engineers at Richard Mille watches and Frédéric Garinaud’s team at AP Renaud and Papi who have developed and continue to develop the watch. Although the design is finalized, the watch remains in a constant state of development until the last of the special edition of 30 is completed. It is Richard Mille against the stone, and progress is wrought of attrition rather than a single moment of triumph.

When I first saw the initial drawings on the RM018 back in 2006, the drive train itself was composed of rose sapphires of various colours that would be finished into cog wheels. This proved to be an unworkable idea. It is not that the sapphire could not be fashioned into a cog wheel (quartz was also tried and would have provided a nice angle on the phrase ‘quartz watch’), but that the colour of the stone was lost when cut to a thickness of about a millemetre. Instead of the translucent colours of blue, green, or rose, there was only a clear or opaque veil of the colour, and while still interesting, was not the intended effect.

Since the initial idea, the switch was then made to semi-precious stones. Each watch, rather than being the same in terms of the stones used, would now have the drive train consisting of one type of stone. Each watch would be unique. With the change in the use of which stones to use, there was also a new set of problems to overcome. Chiefly, how to bind the semi-precious stone to the brass cog wheel element so that it would not come unstuck, that the stone would not stay still as the brass cog element freely moves with the others. The time keeping properties of the watch would be lost.

I have always argued that Richard Mille watches are where haute horologie meets the cutting edge of material science, and here he demonstrates this once again. The ability to bind a semi-precious stone to brass, so that the forces acting on the circumference of the stone where it meets the metal, is a unique solution. The problem in the solution is getting it right! The solution is one of trial and error, each and every time a new cog wheel is created. It is laborious, time consuming, and requires commitment to see this process through to the end product.

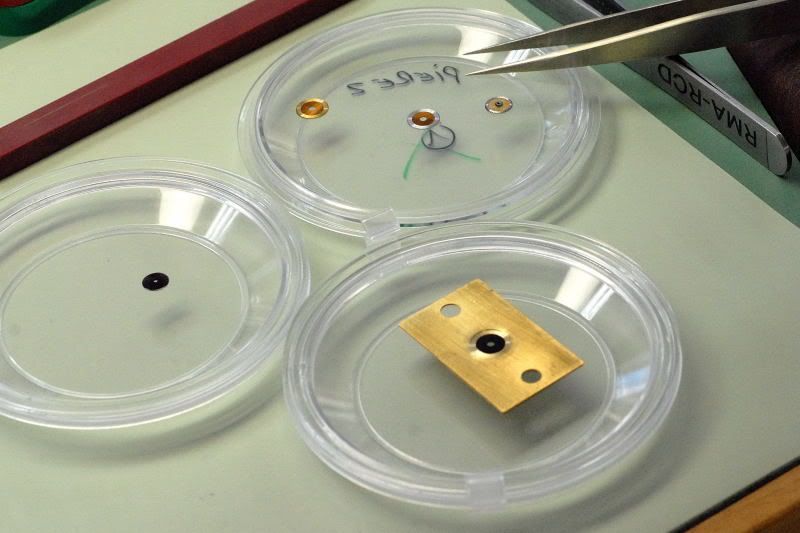

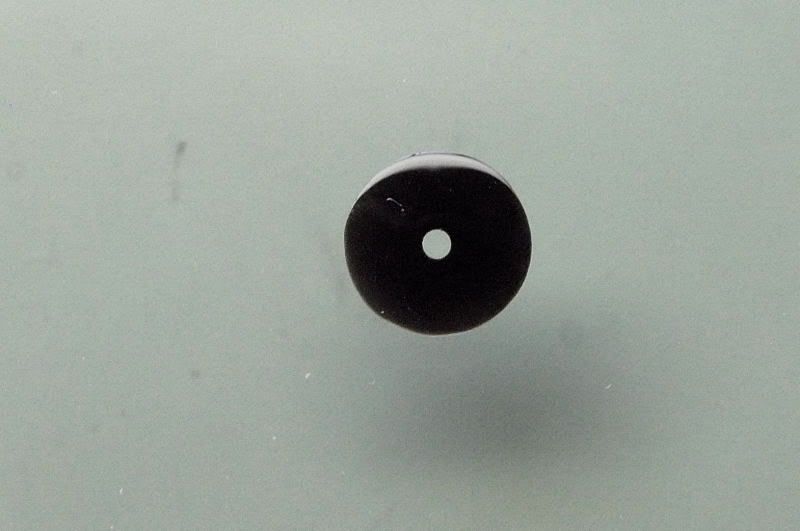

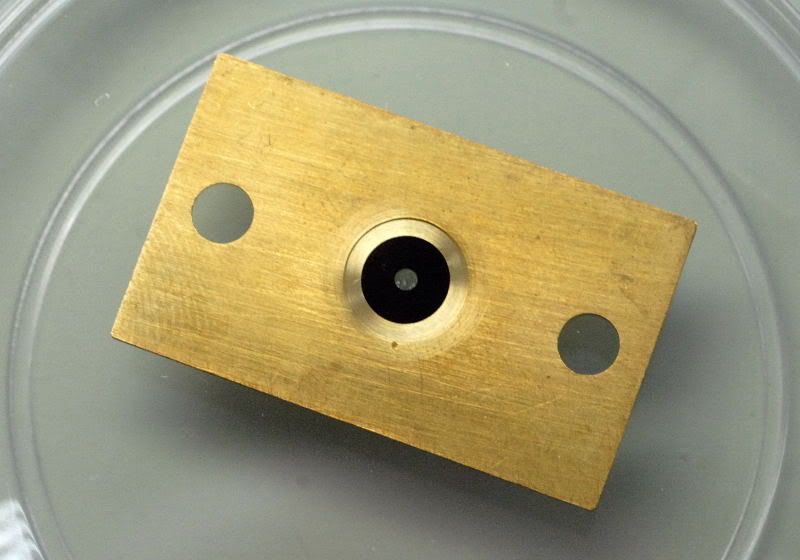

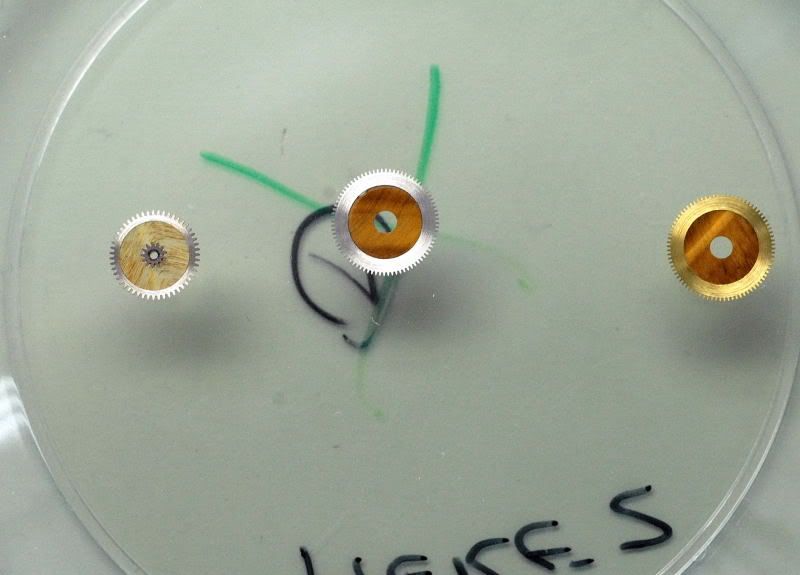

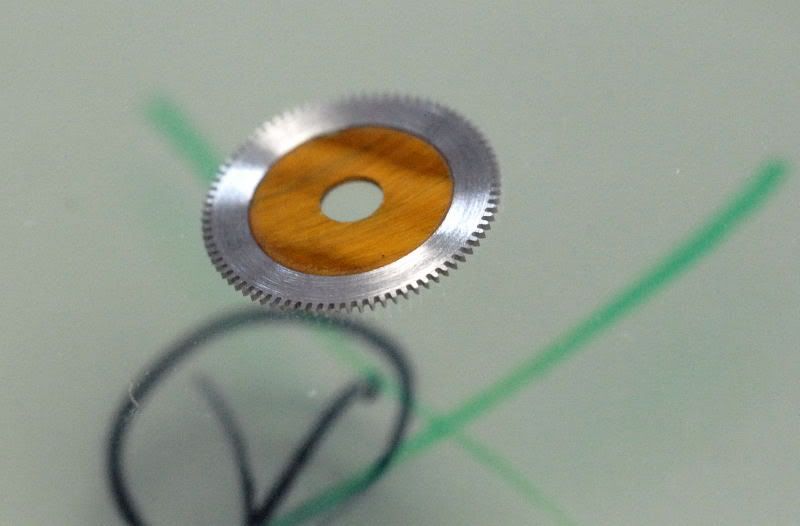

Each cog wheel is created thus. First, you select your semi-precious stone and machine a cylinder shape at the required diameter. Second, slice a part of the cylinder and then machine that to the required thickness. Polish, and finish to an exemplary standard. Third, obtain a piece of brass and drill a hole that is the same diameter as the circumference of the stone, only minus a very small (almost infinitesimally small) difference. Fourth, heat the brass plate with the hole so that the hole then expands to just larger than the diameter of the stone. Place the stone in the hole and allow the brass plate to cool (contracting the metal) so that the metal contracts around the stone, and equal pressure is applied at all times to the edge of the stone, thereby bind the stone to the metal. Cut out the cog wheel to the desired circumference and number of cogs.

[The basic building blocks: to create the cog wheels]

[A polished onyx wheel]

[The onyx wheel set within the brass plate]

Once the metal has cooled, and providing there are no further problems during the machining process, a cog wheel can be cut from the brass plate with the semi-precious stone set within.

Sounds so easy, so what can go wrong? Just about everything! At this level of micro engineering and materials science, the forces being considered are small, but still sufficient to cause problems. If the stone and the hole are not exactly circular in shape, then the forces acting on the stone are not constant and the stone can crack. If the stone is just too large for the brass hole, when the metal is allowed to contract, the stone will crack. As the exact composition is not known for the brass, the heating and cooling properties of the metal can only be approximated (remember we are dealing in dimensions of a micron here), and hence this can cause the stone to fall from the metal, or again, crack. The internal consistency of the stone is unknown; it may look perfect on the outside once polished, but inside may contain a minute fissure and once again, the stone can crack once the metal contracts around it. And so it goes on. The failure rate, even when the stone has passed the basic tests for its ability to be used in this process, is still very high. I asked, but was told that it was not known for sure. When I pressed for a ‘back of the envelope’ number, I was told it was upwards of a 90 percent failure rate. Each semi-precious cog wheel is a hard fought battle won.

[An example of a failure: once the metal had cooled, the onyx stone cracked]

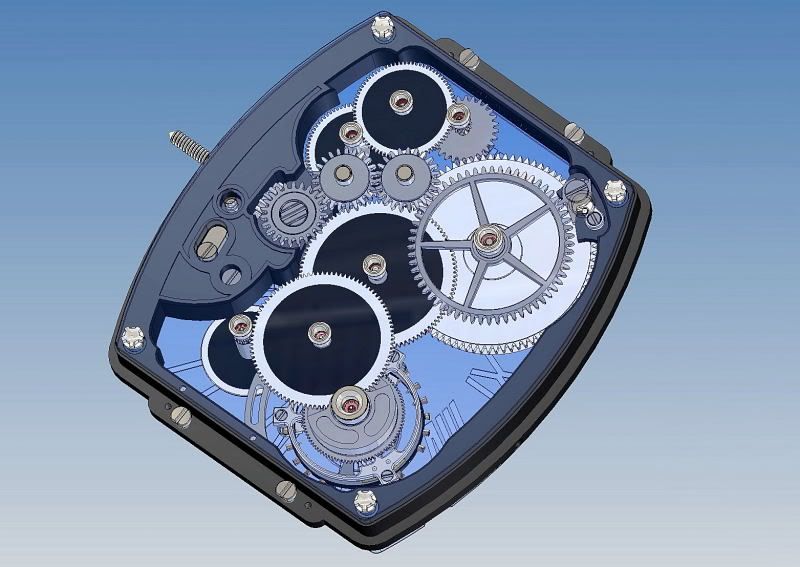

More cog wheels are assembled than are needed as the watchmaker will choose which sets of wheels give the most aesthetically appealing configuration in the body of the watch. The watch is then assembled, with crystalline plates giving the impression that the movement is ‘floating’ in the centre of the watch case.

The computer rendition of the movement provides an idea of what is otherwise a simple tourbillon movement with a power reserve and off-centre secondhand, but that the movement is ‘held’ between the two plates with chatons providing the pins/pivots on which the jeweled cog wheels sit. Even getting the crystalline plates right, with the exact depth and drilled holes at the exact places without cracking the crystal plate, and then fixing the chatons, has also been time consuming and not without problems.

‘A Jewel of a Watch’: the Richard Mille RM018 ‘Hommage a Boucheron’.

Friends from Place Vendome

Perpetual Research

They are making wagon-wheels!

Inspiration can come from anywhere! True - and if

A Unique Watch in Every Sense.

Stunning timepieces.

I think once all watches are assembled, it would be

Andrew, well done and thanks for sharing.

Thanks Andrew for this wonderful review!

Thanks Anthony - yes, all will carry the same engraving

You really should try to get to see one in the flesh...

Awesome RM report and pics Andrew!

Finally rational....

It is a winner - technically and aesthetically about as

I saw a press photo of the tiger's eye version...

Thank you for the kind words Daos - the watch when

Thanks for the great report Andrew. Any idea

As the stones are kept in place by frictional force, they should

It's not a juxtaposition one would normally expect . . .

Amasing...

Yes, the watch has had a full-time team for the last 3 years!!

A LOT! But considering the uniqueness, research, and originality

Wow... Those are beautiful...

Great report...

But then it would not be 'Hommage a Boucheron'. It is a

Richard, as we will see a little later this year, is perpetually

Thanks a lot Andrew for the post.