219

3826

“Wings of Desire”: Richard Mille’s RM021/RM022 and Orthorhombic Titanium Aluminide

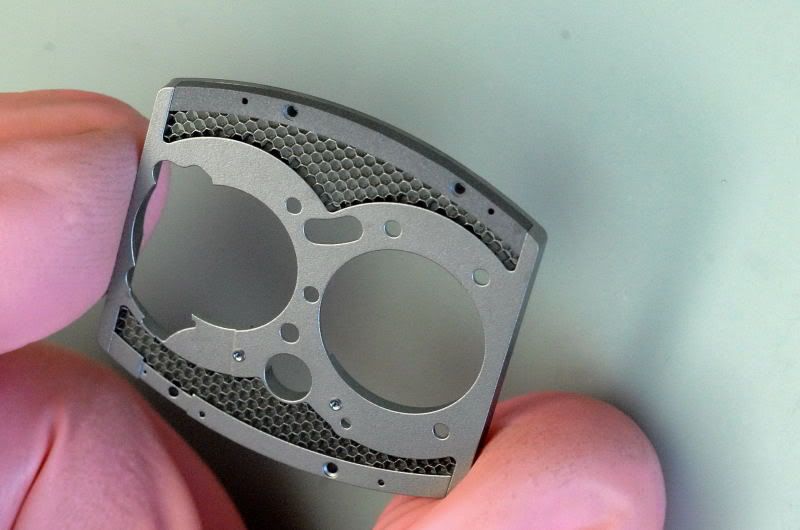

[The baseplate for the RM021. As described below, the simplicity of its appearance belies the techniques and technology that underlie its production]

[One of only 5 in the world: this one at Harrods RM Boutique in London, the new stealth watch from Richard Mille – the RM022 Carbon]

Introduced in 2009, the RM021/022 watches were Richard’s new standard tourbillon watches: the ‘basic’ time only and the GMT. And while we had come to expect the innovative and new material science stance from Monsieur Mille, the watch perhaps did not get the attention it deserved. Talking with Yves Mathys (General Manager at Richard Mille Watches SA), he reflects that perhaps it was not the best time to launch a new tourbillon. The series was slow to get started and demand for tourbillons generally in 2009 and 2010 were not as high as usual. Hence the RM021 and RM022 watches did not ‘take-off’ in the market as expected.

It was strange, here was a new design for the Richard Mille tourbillon line, new baseplate material that even now is still somewhat overlooked, new case design, and yet sales were slow. Sales have started to pick up now, especially with the recent limited editions of the RM022 Carbon (with carbon nanofibre parts and carbon nanotubes case). Perhaps here, in this stealth bomber attire (literally – and I will come back to this), the new baseplate material has found a home in the Richard Mille tourbillon series. For while the baseplate looks a simple lattice work of hexagonal metal, the orthorhombic titanium aluminide baseplate is made to the same standards as the metal contained in the stealth bomber wings and engines. The story of this material in the RM021 and RM022 has remained hidden and hopefully this article will shed some light on the missing information.

Initially, the prototype baseplate was housed in ceramic, but for the limited edition RM022 Carbon, the watch has a carbon nanotube housing. More than we know, this is a watch borne from the aeronautics industry. Unlike some other brands where the pattern might be a façade, something fastened to the baseplate for effect; within the RM021/022 series the honeycombed pattern is the material. Admittedly, the baseplate is unique in its use within the watch industry. Where Richard had started with the carbon nanofibre baseplate and seen others in the watch industry start to use carbon to some degree; Richard moved away and used other lightweight materials that are nonetheless impervious to every day deviations in temperature.

Frederic Garinaud and Frederic Magnard, the concept engineers behind the use of the orthorhombic titanium material in a baseplate, were both trained in aeronautical engineering. They started with the orthorhombic as a concept piece for a new baseplate having worked on the carbon nanofibre baseplate for the RM006. The orthorhombic material had been shown to Frederic Garinaud at an aeronautics show in 2006 in France and the concept baseplate that was produced was one that would be a ‘true’ baseplate (that supported the movement) and was not there for decoration.

At the time of seeing the orthorhombic titanium material, it was only two years since the patent was approved (United States Patent 6758388 - www.google.com What made this material different was obvious for anyone whose first concern was saving weight. Not really needed within a watch, admittedly, but the baseplate did bring with it a new aesthetic. The material itself, titanium aluminide was not a new alloy; or the shaping and combining it with a ‘honeycomb’ structure. What was new was the way the materials were combined with a brasing technique to combine the titanium aluminide structure with the other metals that would be either top, base, or on the side.

Using a metal alloy that was (and is) pure rocket science, the subject of NASA research into an alloy that would allow lighter turbine and aircraft wings, with less corrosive problems, it seemed a strange choice for a base plate. Until you see the watch, the unusual bridges for the main spring and for the tourbillon (that are slanted metal that catch light in different ways) and the base plate itself gives the watch details that at first appearance are missed. This is not a decorative feature but an integral part of the plate itself. The orthorhombic titanium aluminide (orthorhombic TiAl (OTiAl) honeycomb core) has unique properties, one of which is the ability to act as a metal that can be soldered like any other metal. Hence, around the edge of the orthorhombic titanium aluminide is titanium that can be used to mount the movement parts and then the movement into the case.

Reading the patent on the techniques for constructing the material, it seems deceptively simple! Indeed, simply take a “…relatively thick (0.0008 to 0.006 in., preferably about 0.002 in.) metal braze filler foil of an alloy containing copper, titanium, and optionally nickel.” Now comes the ‘mind boggling’ part: “Preferably, the assembly may be heated to a temperature in the range of about 1700 F to 2200 F for a braze soak time of between 1 minute and 150 minutes to cause melting of the metal foil and brazing of the honeycomb core and facing sheet(s) faying surfaces.” Depending on how you want to do this exactly, all the heating and bonding of metal surfaces as described takes place in a vacuum furnace, and the metal surfaces are bonded without cracking. Cooling the metal after heating it to such an extreme temperature requires time. There is also the problem of applying and maintaining the pressure necessary and consistently so that the metals braze with each other.

So even though the orthorhombic baseplate might look a relatively simple thing, it is not. As some other watch firms have used a façade or pattern that is similar, it is probably lost on most of us (myself included until I started the research for this article) that for the RM021/22 series, the base plate for the watch is constructed in much the same way as the metal wings or parts on a high performance jets. In the same way that Richard had always been concerned with technique, it is the technique of manufacture for the baseplate that is completed in the same way as the wings that control the afterburners on the jet engines. It is the same orthorhombic titanium aluminide that is lies in the small wings, that are heated and cooled to extreme temperatures, and it is the same techniques that are used to construct the baseplates. I would agree that such temperature variations will never be needed in a wristwatch, but the techniques for manufacture are the same. The orthorhombic titanium aluminide is an integral part of the movement baseplate; it is not simply stuck on. It will not corrode or warp over time to temperature variations!

Given the requirements for manufacture, the orthorhombic titanium aluminide baseplates are expensive to manufacture, and in keeping with the carbon nanofibre baseplates, the only place where you can get such a specialized order made is in the US. The orthorhombic baseplates are different from standard baseplate production because each one has to be produced separately. This is not a case of getting a ‘blank’ and placing it on a CNC machine, pressing a button, and getting a baseplate at the end of the machining process. No, this is a highly specialized individually made baseplate for each watch. The profile of the baseplate has even been shaped to resemble that of a wing: fatter in the middle part, thinner at the outer edges. While Richard’s aim is to keep the watch manufacture in Switzerland, in the high technology, very specialized areas, he has to turn to the Aeronautical Space flight specialists, who usually supply to NASA, to produce what is required. From their training, and from their inside contacts in the industry, Messrs Garinaud and Magnard provided the knowledge for the idea and the production of baseplates by the necessary high technology firms.

===

For the rest of Andrew's article in Richard Mille forum: richardmille.watchprosite.com